Cruncher G70

Extreme power – amazing production

Main advantage of the Cruncher (G-series) is the standard integrated booster system, a unique feature designed by NPK. This booster system automatically activates whenever the jaws meet resistance. Compared to competitive crunchers without such a booster, the pressure intensifier system has a relatively low oil flow and produces faster cycle times and more crushing strength.

Additionally, other excavators functions remain uninfluenced. The integral booster allows a compact body design, reduces the total weight of the attachment and affords ease of maintenance.

The cruncher is specifically designed to reduce oversized concrete pieces from ground level after they have been demolished. Simultaneously the reinforced steel will be separated from the concrete on site! This results in a significant reduction of transport costs and recycling becomes much more efficient.

Advantages

- Standard integrated booster system that automatically activates when the jaws meet resistance.

- Easy maintenance.

- Bolt on Tooth plate: easy teeth replacement.

- Large jaw opening.

- Piston rod fully protected against damage.

- Low oil flow – other functions of excavator are not influenced.

- Short opening/closing time (3.3 sec.) in unloaded condition, produces 18 cycles a minute.

- High productivity and extreme power.

- Designed and produced by the world’s largest manufacturer of boom mounted attachments.

- Standard rebar cutters.

- No additional pressure reduction is required in the hydraulic system.

- Worldwide sales and product support network.

Specification

| Model NPK | G70 |

| Excavator weight (ton) | 6 – 10 |

| Weight (kg) | 690 |

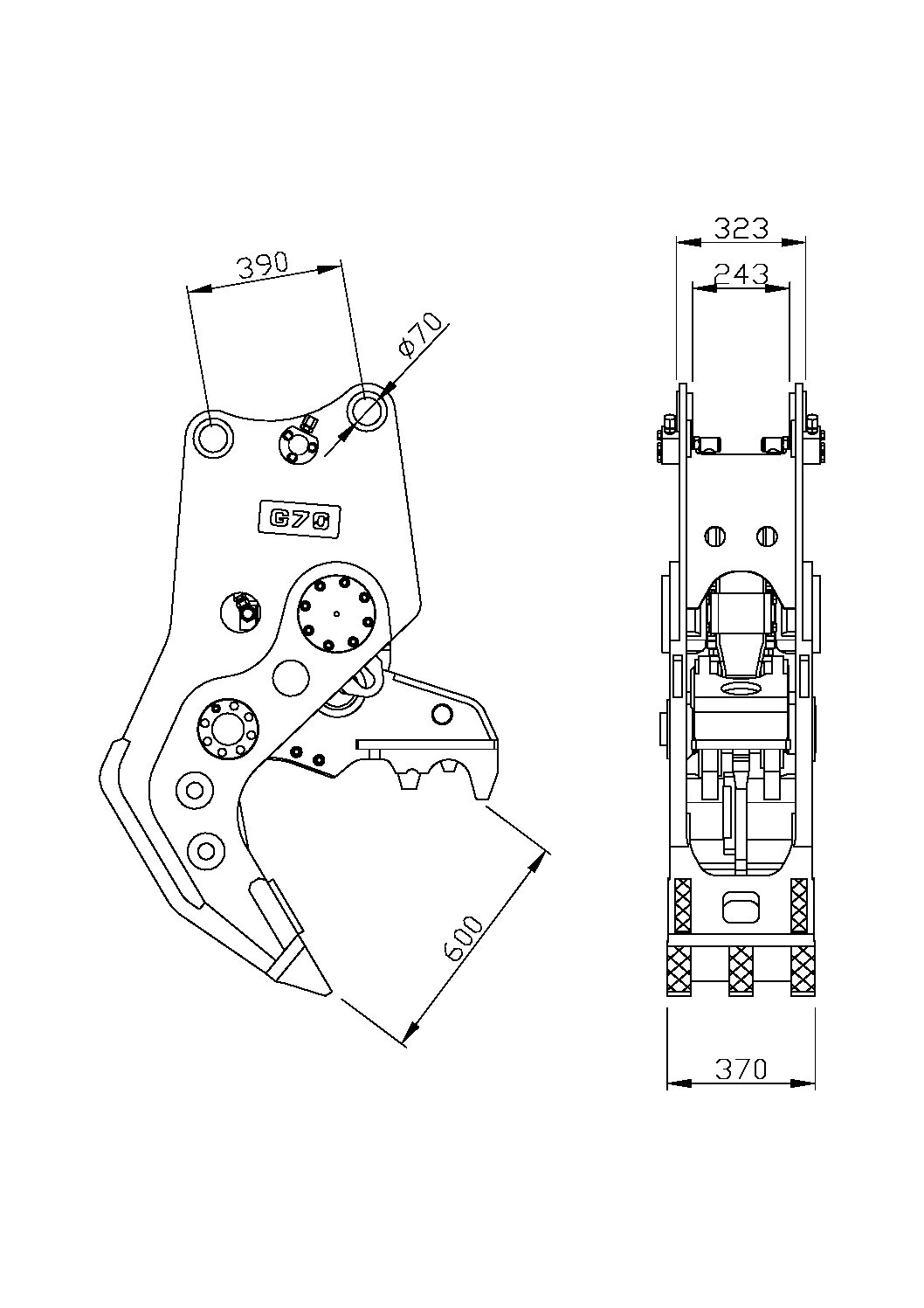

| Max. jaw opening (mm) | 600 |

| Working pressure (MPa) | 26 |

| Oil flow (l/min) | 50 – 130 |

| Max. force (A) (kN) | 410 |

| Max. force (B) (kN) | 550 |

Productivity

| Model NPK | G70 |

| Opening time (sec) | 0.8 |

| Closing time (sec) | 1.3 |

| Total cycle time (sec) | 2.1 |

| Number of cycles (c/min) | 29 |

| Oil flow (l/min) | 130 |

Drawing